Company Introduction

IT BUSINESS

Membrane / Filter BUSINESS

Bio / Medical BUSINESS

Investment Information

Ethical Management

IT BUSINESS

FPCB

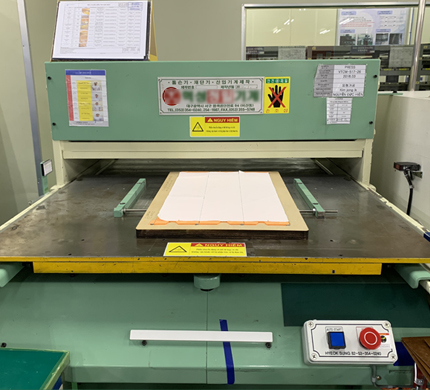

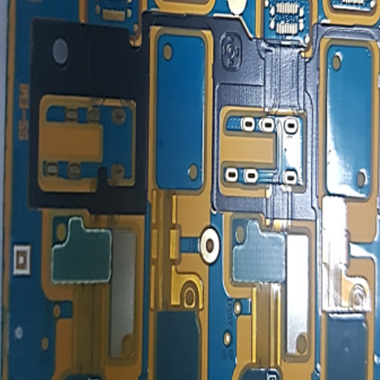

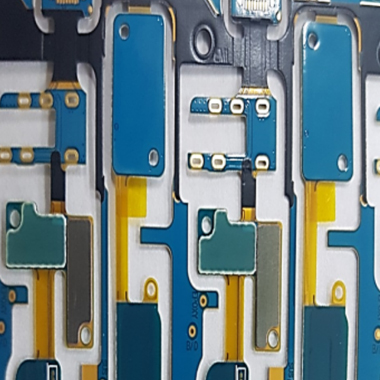

Press

Description

This is the process of cutting out the external shape after finishing all the processes of the FPCB. It is a process to process the external shape of the desired FPCB with instant punching by attaching a set of molds consisting of upper and lower plates to a pressure punching press.

Work process

1.COPOUND

- ①KNOCK OUT.

- -A method in which the punched product is immediately detached from the KIT

- ②PUSH BACK

- -A method in which the blown product is attached to the product kit and is removed later

2.PIECING

- -When punching, the SCRAP falls down

Main equipment

PRESS |

Thompson press |

Automatic punching machine |

Before and After Work

|

|

| image before work | image after work |

Do you have any inquiries?

Please register your questions. Will respond with sincerity as soon as possible.